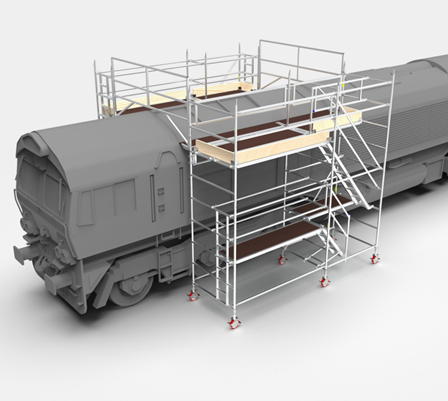

Providing Practical Roof Access Solutions for Class 66 Locomotives

Project Requirements

The access system needed to provide a safe, compliant, guard-railed 4m² working area at roof level, while accommodating the locomotive’s angular roof profile. Several key challenges were identified early in the design process.

Cantilevered guardrail frames were ruled out due to:

- Limited safety performance of folding guardrail sections.

- Complexity and time consumption during assembly and relocation.

- Increased risk of instability when moving equipment.

- Inadequate provision for secondary access or escape.

The client requested stair access as the primary means of entry and exit, with a strong preference for equipment that could be dismantled and stored efficiently.

Solution Development

Building on the Alto HD 1139 modular system, and introducing additional purpose-designed components, we delivered a solution that met both operational and safety requirements.

The structure includes:

- Linked double-width towers with gated upper-level access.

- Rigid roof-edge guardrails shaped to align with the locomotive roof profile.

- Drop-down bridging panels for safe transition onto the locomotive roof.

- Single-width linked towers providing secondary access without restricting ground movement.

- Handrailed staircases for main access and egress points.

- Comprehensive assembly and dismantling documentation aligned with PASMA competence standards.

Further System Enhancements

Following successful implementation, the client requested additional functionality. We designed and supplied a secondary lateral bridging unit at buffer beam level, enabling safe access to the front face of the locomotive and hop-up access to the horn box equipment.

Project Impact

The tailored access system allowed the client to carry out maintenance tasks safely, efficiently, and in compliance with current work-at-height regulations. It also provided operational flexibility by allowing the system to be easily relocated and stored as needed.

This project demonstrates Alto Access’s technical expertise and ability to deliver cost effective access solutions that meet specific industry demands without compromising safety or operational requirements.

)

)